|

|

|||||||

| FM/DM threads Everything about FM/DM in CoD |

|

|

Thread Tools | Display Modes |

|

#11

|

|||

|

|||

|

Quote:

Let's be very clear on this point.:  Quote:

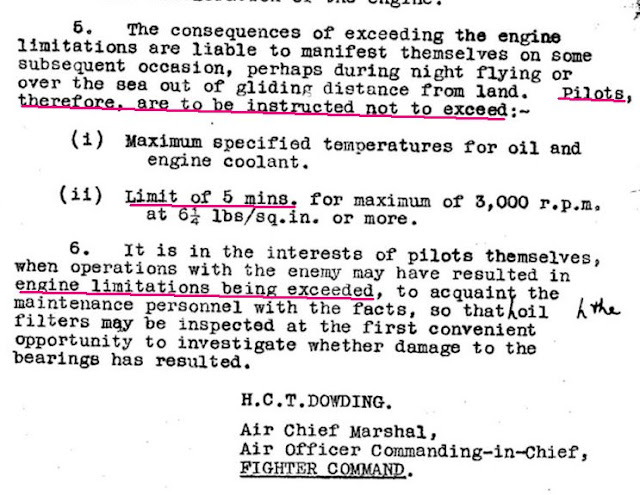

I have read through every source on the Merlin engine that I have, and all the combat reports at: http://www.wwiiaircraftperformance.org/ From what I can gather, Merlin engine failures, were primarily random events and the main culprit was manufacturing defects/design faults that eventually break the engine. The 50 hour 12lb/3000rpm test is an example of this, where the engine was cycled 100 times at 5min/20min at 12/4.5lb boost and eventually developed a coolant leak from a defect that plagued service engines that were not being run past 6.25lb. The Merlin in Perspective states that fighters had a higher propensity for coolant leaks than bombers because fighters were cycling engine power from very low to very high much more frequently, but this was still not a common occurrence. The next greatest problem was bearing failure from oil starvation, and again 12lb boost had little to do with this except for prolonged steep climbs, as per Dowding's memo, but probably the greatest cause was inverted flying and prolonged dives that caused excessive (~3600) RPM. 1939 Merlin TBO: Fighters: 240 hrs Bombers: 300 hrs repair depots: 1942 onward: 35% of engines were there due to time expiry. 1942 onward: average engine under repair had 60% of nominal life, or 144 hrs for a fighter engine and 180 hrs for a bomber engine. I would propose the following: Any engine has a 65% probability of random major engine failure, during 240 hrs of operation, or about 160 sorties. Another way to express that would be a 6.5% probability of one aircraft out of 16 having major engine failure on a typical mission. I don't know how to model the use of 12lb/3000 rpm for more than 5mins, but a simple way would be be multiply the failure probability by, say 1.15, to simulate the increased RPM and stress on the engine. |

| Thread Tools | |

| Display Modes | |

|

|