|

|

|||||||

| FM/DM threads Everything about FM/DM in CoD |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

|||

|

|||

|

Maybe this. The intake manifold is a fixed volume/space. When you increase the throttle in the cockpit, you are mechanically increasing the fuel/air mixture relative to that volume/space of the intake manifold (engine vacume sucks in the air/fuel mix). There must have been a pressure sensor at the intake manifold that reads the fuel/air pressure and feeds the ata gauge its reading.

More air/fuel makes engine cycle faster and must be offset by increased load to keep from over-rpms. Too much fuel/air when the engine is under heavy load means there isn't enough vacume (due to low rpms) to handle the increased fuel/air and the engine lugs. |

|

#2

|

|||

|

|||

|

got it

and is this also referred to as boost in other AC? |

|

#3

|

|||

|

|||

|

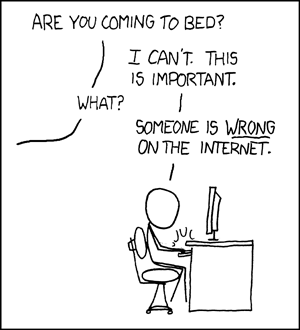

*edit*Curses! Kurfurst beat me to it! I'll leave the comic in anyway...*/edit*

Boost and manifold pressure are the same thing; a measure of the pressure in the intake manifold (ie the ducting between the supercharger and the cylinders). The British convention was to measure this pressure in psi gauge and call it boost; zero boost means that the pressure in the intake manifold is nominally atmospheric (14.7 psi absolute), +12 means atmospheric pressure + 12 psi (i.e. 24.7 psi absolute) and so on. So this system works rather like the pressure gauge on a bicycle pump (except that the scale goes all the way down to -14.7 psi, which would be a perfect vacuum). Almost everybody else decided to measure manifold pressure in absolute units, such that zero would be a perfect vacuum. The Americans use inches of mercury; the Germans use ata. The ata is a rather annoying little unit, because it's not quite what you'd expect. A standard atmosphere is 101325 Pa A bar is 100000 Pa An ata is 98066.5 Pa (ie 1 kgf/cm^2). So when your engine is switched off on a standard day at sea level you'd expect to see a manifold pressure of: 101325 Pa = 0 psi boost = 29.92"Hg = 1.0332 ata. So you can see how lightly boosted the German engines were: 1.42 ata is only 20.2 psi absolute or about +5.5 psi boost. Why do we care? Too much pressure in the intake manifold means too much pressure in the cylinders, which will cause problems for the engine. In particular, detonation. High pressure and long combustion chamber residence times increase the probability of detonation, so you can only get away with so much manifold pressure at any given rpm; you can get away with higher boost at higher rpm, but of course there's an rpm limit too... Also, with a constant speed prop the rpm we get is the rpm we asked the CSU to give us, and this therefore doesn't tell us anything about how much power the engine is producing. Since the power production is basically a function of the engine's air consumption, it will vary roughly in proportion to engine rpm * air density in the intake manifold. Since we can't measure the density of the air in the intake manifold directly, pressure is a pretty good substitute because we know that P*V = roh*R*T All this stuff about engines needing vacuum to run just isn't true. The engine wants as much air as possible. It only creates a depression in the intake manifold when we throttle it. It can't get as much air as it wants to, and so it sucks down the pressure in the intake manifold. But if you open the throttle of a naturally aspirated engine then the pressure in the intake manifold will rise to (almost) ambient pressure. If the engine is supercharged, the throttle is almost always upstream of the supercharger. An early Merlin has a supercharger pressure ratio of about 2.7 at 3000 rpm. So if the engine ran unthrottled at sea level then the manifold pressure would be about 2.7*14.7 = 39.7 psi, which is +25 psi boost. This would cause rapid engine failure due to detonation, and even if you put 150 grade fuel into it, an early Merlin just wouldn't be physically strong enough to stand up to the cylinder pressures produced for more than about 15 minutes or so (though for that glorious 15 minutes it would put out over 2000 bhp). Last edited by Viper2000; 04-17-2011 at 11:09 AM. Reason: Kurfurst beat me to the punch |

|

#4

|

|||

|

|||

|

so the ata gauge is actually used for a few reasons.....for keeping the intake manifold pressure to the values specified in the pilot's notes for peak performance during the different work loads ...and also just as importantly it's used to prevent engine failure due to detonation....or what I've always referred to as "knocking"

great info guys...you know I googled about this earlier today and was unable to find anything about this subject...this will probably help out quite a few of us who are new to this somewhat more demanding CEM. |

|

#5

|

|||

|

|||

|

Yep, and a sticky thread would be a good idea too.

|

|

#6

|

|||

|

|||

|

did a little testing on detonation with the spit mkIIa.

sea level, throttle to max, boost cut out (the instrument was reading +9, but that's the max), pitch to a minimum (1700 rpm). the plane flew on for 20 minutes. no damage. I thought this was the worst possible scenario for detonation (max pressure, min rpm). did the same thing with max rpm (3100 rpm) this time intermittent black smoke appeared, (that would go away if i put boost level back to +6), but again no damage. after another 15 minutesi grew tired and closed the radiator, which led to "perforated water radiator" in a few seconds. what am i doing wrong? i thought the engine were much easier to damage. |

|

#7

|

|||

|

|||

|

Likely the spit's constant speed unit won't allow you to do as much damage with the governor in place, verses 109 where you can directly control the load (in manual prop mode) and screw it up really fast. In other words, they probably designed the CSU as much as possible to mitigate the extreme situations on the engine (lug and over-speed).

|

|

#8

|

|||

|

|||

|

many thanks for the explanation.

One question: how do we control the manifold pressure/boost? only with the throttle? meaning that if we see the pressure is over the limit for a specific rpm, we have to throttle back? nothing more? Also, if with increasing altitude the pressure drops, this means we will be able to open the throttle more? (btw is detonation modelled in the sim? how do i recognize it?) |

|

#9

|

|||

|

|||

|

Quote:

Today we'd talk about the "left inceptor" in a fighter rather than the "throttle". But of course, jets are basically single lever machines thanks to the wonders of automation. So the left inceptor is just the "go" lever, and it doesn't control any specific mechanical part; it asks a computer for more or less thrust, and the computer then decides how to deliver it, which will involve all sorts of stuff (fuel flow, variable geometry etc). Actually, the intellectual basis for this technology dates to the late 1930s. For the purposes of this discussion, we need to make a clear distinction between mechanical stuff and the cockpit controls. The cockpit controls are

1 - Power control lever The throttle valve controls manifold pressure by producing a controllable isenthalpic pressure loss in the induction system. Full Throttle (FT), also known as Wide Open Throttle (WOT) means that the valve is open, so the throttling loss is as close to zero as the designers could make it. The throttle valve may either be controlled directly by the power control in the cockpit, or it may be controlled via Automatic Boost Control (ABC). ABC may either be single acting or double acting. A single acting ABC just limits throttle valve opening to prevent the pilot from exceeding the engine boost limit. So no matter how far you move the power control forward, you can't exceed the rated boost. The problem with this is that if the engine is heavily supercharged, at sea level you might reach rated boost with the power lever only slightly opened, so fine power control at low altitude is difficult. As you climb with a single acting system, if you're at less than rated boost you'll have to continuously open the throttle to maintain boost. However, if you move the power lever far enough forward for the ABC to be limiting, then the ABC will obviously open the throttle during the climb until it reaches the throttle position corresponding to the cockpit power lever position (ie if you "firewalled the throttle" then it'd open the valve all the way; if you moved the control say 80% of the way forward then the ABC would open the valve to 80% and then stop). Single acting ABC units were replaced in the late 1930s by double acting ABC units. A double acting ABC is an attempt to turn the cockpit power lever into a boost controller, such that a fixed power lever position will produce fixed boost. However, there were certainly limitations to this technology in 1940, and eg for Merlins the ABC was only genuinely double acting when the power lever was forward of the position for maximum weak mixture boost (see AP2095). This meant that during climbs at partial power the pilot would still have to keep an eye on his boost gauge and advance the power lever to maintain boost above a certain altitude. An additional complication was the advent of combat concessions. Engine development in the 1920s and 1930s brought forward the concept of safe overhaul lives. It was realised during the development of racing aeroplanes, such as those used in the Schneider trophy races, that there is a relationship between the power output of an engine and the length of time it is likely to last before failing. Tightening up of metallurgy and production processes meant that engines became more and more predictable, and so it was possible to have considerable confidence that an engine would last for say 100 hours at a given rating. A rating is a collection of all relevant operating parameters (e.g. boost, rpm, supercharger gear, ambient conditions, oil and coolant temperatures etc). However, the way in which people actually operate aeroplanes is such that various different power levels are used in any given sortie. A fighter aircraft might have a sortie like this

You can see that the sortie involves running the engine for 121 minutes. Of that sortie, 5 minutes (4.1%) was at combat power, and 2 minutes was at takeoff power (1.7%). Lumping the two together, we have about 7 minutes of really high power running, which is 5.8%. In 1940, the life of a Merlin in a fighter was nominally 240 hours, and would have been based upon something like the sort of usage above; perhaps 6% of total running time at high power - say 14-15 hours out of the 240. In reality, from 1942 onwards the average was that about 35% of engines made it to their nominal life; the average engine made it to about 60% of its nominal life before passing to a repair organisation. Of course, quite a lot of engines ended up being damaged by other factors (enemy action, pilot error etc). Anyway, the point about the time limiting of combat concessions to say 5 minutes was not that the engine would fail after 5 minutes 1 second, but that using the engine at combat power consumed its safe life at a considerable rate, and therefore both increased the risk of subsequent engine failure (potentially whilst the aeroplane was being flown quite gently by another, totally innocent, pilot) and the general burden on the maintenance organisations. And of course, aeroplanes which are being worked on in the hangar can't fly combat sorties. Because life consumption is really disproportionate at high power levels, efforts were made to discourage its accidental use by requiring additional pilot actions to access it. These included such as operating "boost control cutout*" switches, throttle gates, or sometimes a combination. The boost control cutout was actually a way of changing the operation of the ABC; it didn't completely remove it from the control system as the name implies. Instead, it changed the pressure information that the ABC used to set power, which changed the amount of boost the ABC would allow. Initially, this was a relatively crude system because it would have the effect of effectively "rescaling" the power lever, so that 100% would correspond to a higher boost level with the cutout activated than with it deactivated. This was obviously undesirable because operating the cutout would produce a step change in engine power, which isn't a kind thing to do to an engine. The eventual solution was a gated throttle, such that 100% Power Lever Angle would give rated power, and that positive action to overcome the gate would then allow additional combat or takeoff power to be accessed if required. Today, people flying around in Airbuses generally end up simply moving the throttle into detents for takeoff, climb and cruise and allowing the automation to sort out the details, which is the logical conclusion of this approach. 2 - Propeller control lever The earliest and simplest aeroplane have fixed pitch propellers. The pitch of a propeller is the distance it would travel through the air in one revolution with zero slip - this is exactly the same as the definition of the pitch of a screw. In reality, because the air is of finite density, there is quite considerable slip. The simplest way to understand how a propeller works is to draw velocity triangles. If the aeroplane is flying reasonably fast, the 3 sides of the triangle are:

If you draw this triangle, you can clearly see that the angle that any given section of the blade needs to be at to meet the air at a fixed angle of attack is obviously a function of the flight velocity, the rpm of the blade and the diameter of the section. So the blade chord has to be helical. Note that the lift & drag of the blade aerofoil are defined by reference to the chord, which is itself at a certain blade angle which is set by the velocity triangles. If you change the aircraft's speed, what happens is that the angle of attack of the propeller changes, and this changes the amount of engine torque (and thus power) required to drive it at any given rpm. This means that the engine rpm will tend to change as a function of TAS. If the engine is supercharged and rated such that its Full Throttle Height (FTH) is above sea level, then the amount of power that the propeller has to absorb remains constant whilst the air density decreases. This means that even at constant TAS, the engine rpm produced by a given manifold pressure will tend to increase with altitude. The consequence of this is that the higher the FTH of your engine, and the higher the speed range of your aeroplane, the worse the compromise in its propeller design will be. The ideal solution to this problem would be either to change the gear ratio between the propeller and engine at high altitude, so that the propeller could turn faster and keep the same velocity triangles (which was actually investigated in the early days of flight but is impractical for various reasons), or to change the propeller pitch in order to match the propeller to the new velocity triangles produced under different flight conditions. Unfortunately, making a true variable pitch propeller is impossible, because doing so would require the blades to change shape (if you fly faster, the optimum blade angle changes much more at the tip than it does at the root because of trigonometry - in the limit the blade angle is fixed at 90º at zero radius). The next best thing is to just change the angle of the entire blade. Because of the trigonometry of the situation, this is a compromise; the whole blade can only be at a single optimum angle of attack at one combination of rpm & TAS; away from this design point, different sections of the blade are actually at different pitches, and see different angles of attack. For this reason, it's arguably more accurate to talk about "variable blade angle" than "variable pitch". Changing the blade angle means that you can change the torque required to drive the propeller independent of the velocity triangles. This means that you can control engine rpm independently of power setting and flight conditions. The first attempts to do this were pretty clumsy; the propeller would be designed for the economy cruise point, and then a second, reduced blade angle "fine pitch" angle would be arranged to allow the engine to give maximum rpm for takeoff. In the Dh.98 Comet, the blade angle was set pneumatically. Fine pitch was obtained by inflating a diaphragm; once in flight, the dynamic pressure would deflate the diaphragm and change the blade angle to the "coarse pitch" setting. This was obviously a one-shot deal, so once coarse pitch was set it was stuck until landing. It was rapidly realised that a better approach was needed for more practical aeroplane, and so various hydraulic or electric systems were used to change the blade angle. Initially the blade angle was directly controlled by the pilot, but this was obviously hard work as the blade angle would need to be continuously changed in response to changes in TAS, altitude and engine power output. Therefore, the constant speed propeller was invented. This used a governing system of some sort to control blade angle such that the propeller control was now used to directly control engine rpm instead of blade angle. You can see that there's a common theme here; automation gradually taking over the low level control tasks in order that the pilot is freed up to consider higher level problems; he doesn't care about the precise angle of the blades or the position of the engine throttle valve; he cares about boost and rpm; the automation allows him to control those variables directly instead of indirectly. 3 - Mixture control The nominal purpose of the mixture control is to set the Fuel:Air Ratio (FAR) in the cylinders. The problem here is that the amount of air the engine consumes is a function of power setting and flight conditions, and so maintaining constant FAR requires continual changes in fuel flow. Since it's relatively hard work to actually discover how much air the engine is consuming at any given time, maintaining consistent FAR was never an easy task, especially for a carburettor fed engine. The simplest approach is just to size the carburettor for maximum demand and then play about with the fuel flow into it to keep the engine from misbehaving (i.e. weak or rich extinction, detonation etc). There are several problems with this. Firstly, you may end up burning more fuel than you need to because you'll only know you're too rich when you get on the wrong side of the smoke limit. Secondly, you may end up hurting the engine by running it sufficiently lean that it's in incipient knock for much of the sortie. Thirdly, whatever you do, directly controlling the fuel flow is a pain and will require lots of work. The solution is obviously more automation. The details of advanced carburettor design are somewhat complex, but essentially the air consumption is estimated by using a venturi of carefully calibrated geometry such that a known ratio of total:static pressure is produced at the throat. This is then used to control fuel metering so that the correct amount of fuel is injected into the flow. In order to produce maximum power, the engine needs to run fuel rich in order to stave off detonation (and to reduce CHT for air cooled engines). This is obviously wasteful in cruising flight at reduced power when detonation and/or CHT are not a problem, so you want to use a weaker mixture for cruising. The pilot of a single seat fighter doesn't want to have to think about this in great detail, and so the solution is an automatic system with RICH and LEAN settings for high power and cruise operations respectively, along with special cruise ratings denoting the maximum boost and minimum rpm allowed for cruising with the LEAN mixture. 4 - Single lever engine control Clearly, even with automatic help, looking after the engine is a fairly complex business; I didn't even cover the cooling system, the ignition system, supercharger/turbocharger control and so on. But you can see from the above that actually only certain combinations of control settings are allowable. So I never want really high boost at low rpm with a weak mixture for example. Equally, I never want really high rpm at low boost with a rich mixture, because this is a very inefficient way to use the engine. It's probably reasonable to infer that if I have the power lever all the way forward I care about thrust far more than fuel flow, and that if I have the power lever back quite a long way then I'm probably cruising and so I actually care more about fuel flow than power output. This means that it's possible to go to a higher level of abstraction with the control system, and just give the pilot a single power, or thrust lever, which he can use to decide how much "go" he wants, and then allow the automatics to work out the best way of giving it to him. This was done with several types of aeroplane (such as for example the Fw-190) before the end of the war. The final level of abstraction up from this is of course to say that for navigation or formation flight, the pilot doesn't want to control thrust (and thus to rather imperfectly control acceleration depending upon where he is on the aircraft drag characteristic) but rather his speed, be it EAS or Mach number for aircraft performance, or perhaps GS for navigation. Enter the autothrottle. But other than as an illustration of the general trend toward wrapping up complex control characteristics and shoving them into black boxes in order to allow the operator to be progressively de-skilled, this is beyond the scope of this discussion. 5 - Practical flying TL;DR - Use throttle to control boost, use propeller control to set rpm, set mixture rich unless you're cruising at reduced power. At least IRL, problems with CHT or coolant temperature, with oil temperature or with oil pressure will kill most engines much faster than simply running them at high power settings, because the time limits in the manual are intended to allow the engine to achieve its design overhaul life. In general, it has been observed that limits only matter if you realistically expect to use the aeroplane again. When increasing power, first go to rich mixture, then increase rpm, and then increase power to the desired boost setting. When decreasing power, first decrease boost, then decrease rpm, and finally weaken the mixture. To achieve maximum range, start at the maximum weak mixture boost. Reduce rpm to the minimum level permitted, or the minimum required to maintain your desired cruise speed. If the speed for maximum range isn't in the manual then Vy is probably a reasonable approximation. Remember to clean up the airframe as much as possible (radiators/cowl flaps etc). Use any excess power to climb to the FTH for your boost & rpm in the lowest possible supercharger gear. If this results in a speed considerably greater than the maximum range speed for the aeroplane, just keep climbing to allow the boost to naturally fall until everything sorts itself out. If you're in a hurry, you'll obviously go quicker by climbing to repeat the above in FS gear, but specific fuel consumption will be higher due to the increased power required to drive the supercharger and therefore specific air range will be somewhat reduced. To achieve maximum endurance, further reduce rpm until you're flying at the minimum comfortable speed; if the endurance speed isn't listed in the manual then generally Vx is a pretty good approximation. Since the endurance improvement between best range speed and best endurance speed is only about 10-15%, and many aeroplanes are quite nasty to fly at best endurance speed, you're often better off flying a little faster than the true optimum. *I suspect that the original purpose of the boost control cutout was simply to prevent an ABC failure from fully closing the throttle, and that its later use to provide combat power was what a software engineer would describe as a dirty hack, because prior to the approval of the +12 psi rating, engaging the boost cutout switch and fully opening the throttle would give about +17 psi boost (note that this is not Full Throttle, as a Merlin III supercharger has a pressure ratio of about 2.7 and would therefore deliver +25 psi at sea level on a standard day). Clearly, operating at +17 psi on 87 octane would cause detonation and probably wreck the engine in a few minutes. QED. |

|

#10

|

|||

|

|||

|

now that's an explanation

thank you for taking the time to write all of that. answered a lot of questions; particularly the part about the ABC. didn't know such a system existed in 1940. I think many other people would benefit from it. We need a sticky CEM FAQ topic. |

|

|

|