03-15-2012, 09:24 PM

|

|

Approved Member

|

|

Join Date: Mar 2010

Posts: 106

|

|

Quote:

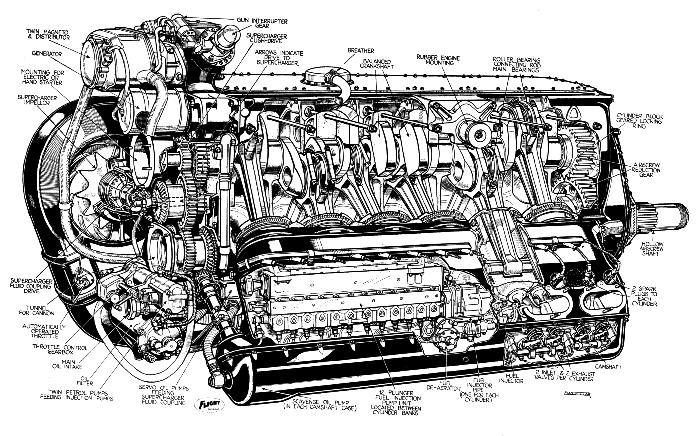

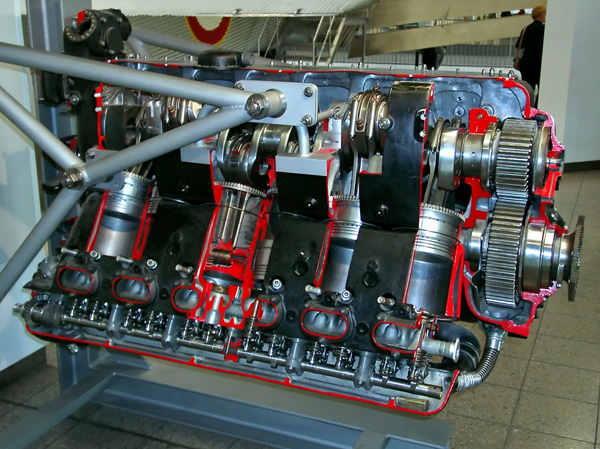

CONSTRUCTION DB 605: Cylinder barrels of steel are screwed and shrunk into the cast Silium-Gamma-alloy cylinder blocks. These dry liners project beyond block providing attachment by means of threaded rings which pull the liners against the finished face of the crankcase. This feature helped to save the weight of the studs and avoided the possibility of distortion. 3

Two inlet and two exhaust valves per cylinder operated by rocker arms directly from a single camshaft carried upon the head. Stellited valve seats, exhaust valve sodium cooled, ball joints interpose rockers and valve stems.

Forged light-alloy pistons have concave heads, each piston has a floating pin and three compression and two oil-scraper rings with one below the pin. Forked type connecting rods with serrated joints at big ends, roller bearing at big end has three tracks of 24 rollers each. Forked rod is keyed to outside of roller race, plain rod runs on lead-bronze bearing over race.

One piece forged steel crankshaft carried in seven plain lead-bronze bearings. Eight balance weights attached to crank webs, splined forward end to receive splined sleeve of reduction gear pinion.

Deep light alloy crankcase with webs at main bearings, tubular mounting at rear below crankshaft for installation of cannon which can fire through propeller shaft, light top cover.

Centrifugal supercharger on port side of engine driven through a fluid coupling by a shaft at right angles to crankshaft. This shaft is driven through bevel gears from the crankshaft, variation in propeller speed secured through variable filling of fluid coupling by two-stage engine driven pump receiving lubricating oil from the main pressure filter.

First stage delivers oil direct to coupling and second stage delivery is passed in varying proportions between crankcase and coupling by piston valve controlled by a capsule which is sensitive to inlet pressure. Second stage cuts in at approximately 5,000 ft. and full delivery occurs at approximately 11,500 ft.

Butterfly throttle which is capsule controlled regulates supercharger delivery, second throttle which is pilot operated controls air supply to engine and manifold pressure, first throttle subjected to pressure between two throttles, increased boost for take-off controlled by clockwork mechanism, mixture delivered by supercharger to looped manifold by large diameter pipe, dry-sump pressure-feed lubrication, gear type oil pumps, spray of oil directed upon reduction gears, main oil pressure line feeds crankshaft bearings, secondary line feeds supercharger fluid pump.

|

|