OK heres what I did for my X52-MSFFB-Pro

I don't have any pics of the joystick top breakdowns but you should be able to figure them out. You take all of the screws out of the sides of the MMffb2 joystick handle and it will split in two. Disconnect the wires from handle to the main board in the MSFFB2 and you can pull that through and then you should just have the black stub from the base of the joystick Where the joystick handle used to be.

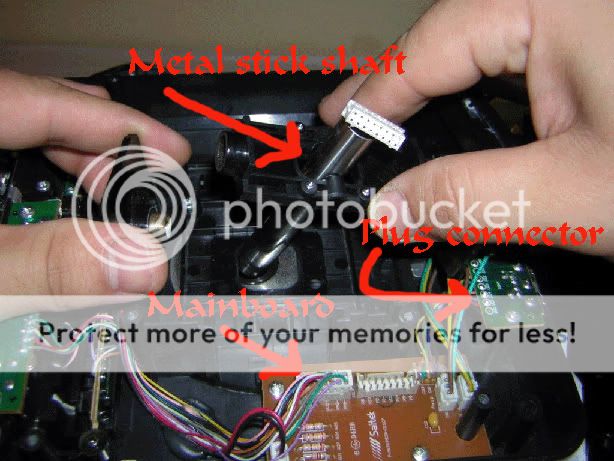

now in the next pic you'll what it looks like in the base of the x-52pro. It's a bit of a bitch to get the metal shaft and joystick handle away from the base. I broke a few pieces out to make it easier to remove. (I knew I wast going back to this joystick base.) You will see where the joystick handle and toggle switches unplugs from the main board do that and remove the stick. Now remove the main board and the connector board from the base.

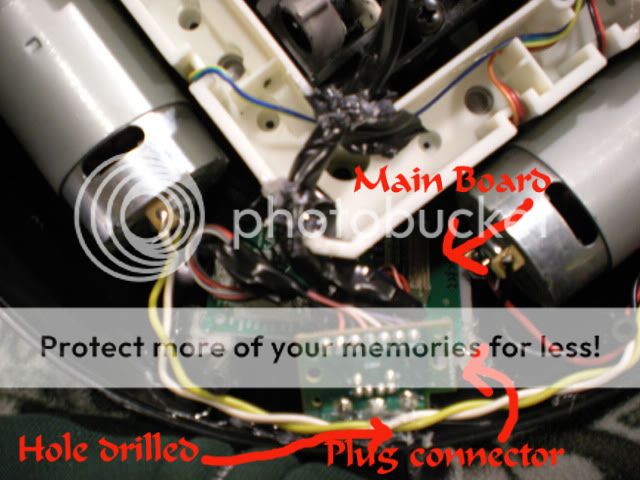

In the next pic you can see where I mounted the main board and connector. Theres enough space there for both.The connector plug that plugs the X52 stick to the throttle is a PS2 type plug I drilled a hole in the side of the FFB2 so just the metal part of the plug went through. I then put a few slivers of double side tape on the edges of the main board and stuck it to the wall to hold it then put some hot glue on the corners to hold it in. I then pushed the plug through into the plug connector board and hot glued the top to hold the board in place and then ran a bead around the outside of the hole at the plug end and it holds nice and firm and you can pop the glue off later if you need to remove the boards

..you can see in this pic where the hole gets drilled and the bead of glue around it.

About attaching the handles

About attaching the handles

Depending on the height you want the handle you will have to cut both down a bit if you want in relatively low. The FFB2 is easy it's plastic. The X52 is metal and the wires are in there. For me it seemed like to much of a pain in the ass to take the stick all apart to pull the wires through so I stuck a screw driver in the shaft to protect the wires from the saw then cut one side of the shaft to the halfway mark then the other.

Joining the two can be done all kinds of way's ...the X52 shaft is a little thinner then the FFB2 so I took a drill and drilled out the center of the FFB2 shaft so the X52 shaft could fit in it or close. Well it didn't go as well as planned and the shaft of the FFB2 cracked when I was forcing the x52 in

It worked out though I put two small hose clamps on it and it's solid as a rock. Later I thought about maybe getting a copper or plastic slip coupler for 1/2 plumbing or what ever size is close to put over both shafts and after cutting some slits in so the ends would clamp, hose clamp it in place that way. Once you have it apart you'll see what I mean and I'm sure you'll think of something.

Let me know if anythings not clear...hope it helps someone S~