|

|

#981

|

||||

|

||||

|

Quote:

Quote:

|

|

#982

|

|||

|

|||

|

We have yet to see the identity of these 16 fighter squadrons from you Eugene.

Last edited by Al Schlageter; 04-17-2012 at 05:51 AM. |

|

#983

|

|||

|

|||

|

Quote:

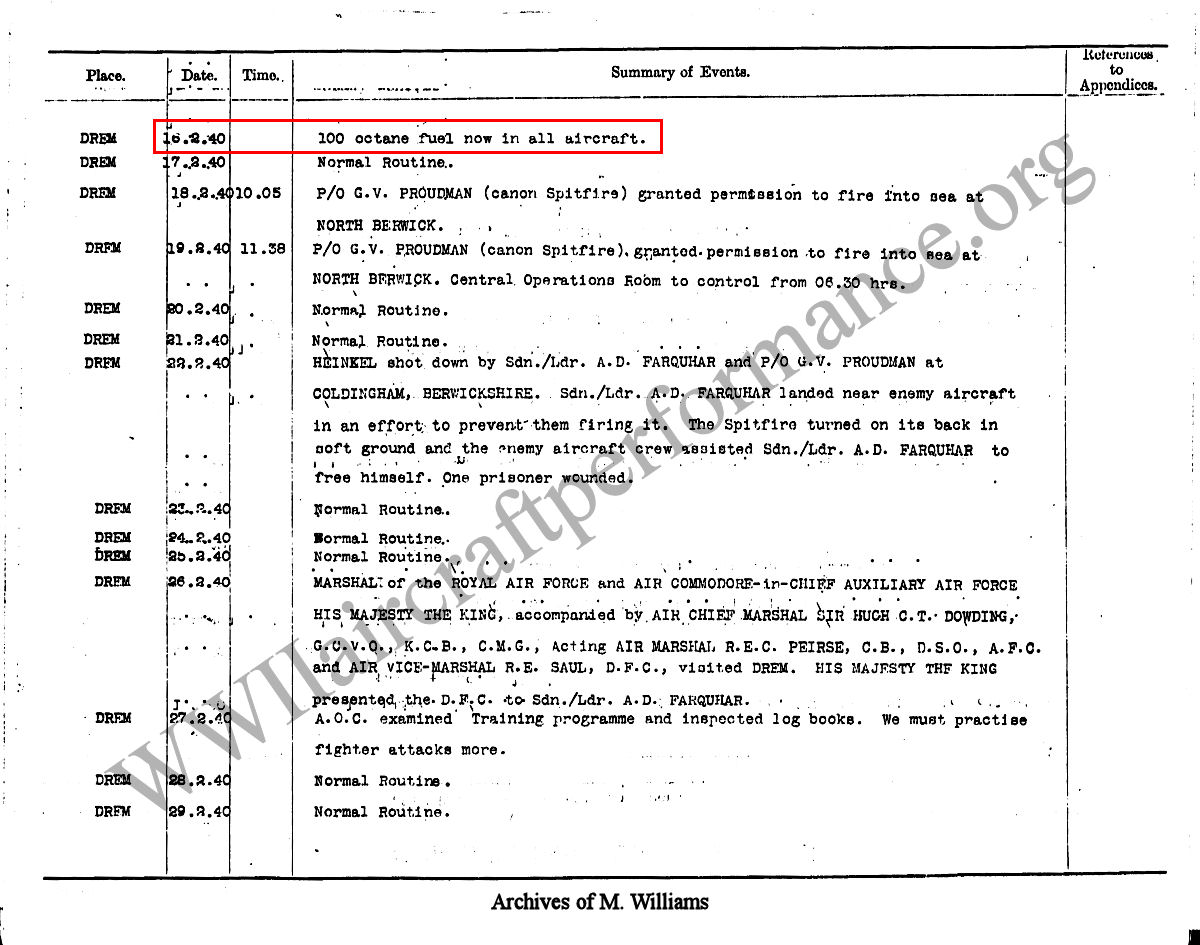

It doesn't mention any modification, only that 100 octane fuel must be used. (Note that the 4th Edition from April 1940 mentions that "sparking plugs approved to withstand this high boost must be used", so if there was any modification required in January 1939 it would have been mentioned.) It does however state that this higher boost setting has to be determined on the ground before it is used by listening if there is detonation. The 4th Edition from April 1940 now gives +12 boost and as already said mentions that specific sparking plugs must be used and that the boost-control cut-out has to be modified to limit boost to +12 boost. Looks like in April the cylinder head modification was no longer required (maybe because all engines had been modified). Last edited by 41Sqn_Banks; 04-17-2012 at 06:48 AM. |

|

#984

|

|||

|

|||

|

Quote:

"Newer engines will already have Mod.No.Merlin/136 embodied" it means what it says - new engines on the production lines - engines being built before the issue of this document - were already being fitted with the modifications. Older engines were also being modified. Ever heard of wartime emergency modifications Eugene? - that means that normal, peacetime practices of leisurely annual maintenance are suspended in favour of ensuring that the latest modifications are embodied as quickly as possible in as many frontline units as possible. A prime example:Starting on June 22 1940, in co-operation with de Havilland, the RAF mounted a crash program to ensure all of its frontline Merlin engine fighters were fitted with Constant Speed propellers "Minutes of a meeting held on June 22nd with the Senior Technical Officer of Fighter Command relate that de Havillands would start the conversion at twelve Spitfire stations on Tuesday, June 25th (less than a week after the first test flight) and could provide twelve men capable of supervising a station apiece; that the firm estimated that each squadron would take ten days to convert, and that all Spitfire squadrons could be completed by July 20th. The same minutes recorded that de Havillands had put in hand the production of 500 conversion sets, without contract cover, and that these would be coming out at the rate of 20 sets daily from June 24th, two days later. Supermarines were to be supplied with 20 sets per week from June 25th for aircraft coming off the production line; this would mean that two-thirds of the Spitfire production from that day onward would be "constant-speed...." The conversion called for this constant-speed unit; a small shaft drive to connect it to the engine; four external engine oil pipes; a complete cockpit control with conduit, and detail parts. The airscrews did not have to be changed, having been designed for constant-speeding, but each had to be dismantled to move the index pins so as to give full pitch range....As Rolls-Royce could not, consistent with other heavy demands, produce the quill shafts for driving the c.s. units, or the engine oil pipes, the data were given to de Havillands and the facilities of the Gipsy engine factory were pressed into service to make over 1,000 sets of these parts. Everybody in the D.H. organisation who could contribute anything was transferred to this job.... The working times of the D.H. engineers during the ensuing weeks averaged about 105 to 110 hours (15 to 16 hours a day), with instances of 130 and up to 150 hours (19 to 21½ hours out of the 24). At some squadrons as many as four and five Spitfires were converted and test-flown in a day.... An entry dated Friday, August 2nd, records that by then, 44 days after the test flight of the first converted Spitfire, the production of conversion sets for all existing Spitfires (more than 800 sets, fulfilling the schedule of 20 a day) was complete, and they had therefore started producing for the Supermarine assembly line; De Havillands then had 400 Hurricane conversion sets in hand and expected to convert a total of 700, after which constant speed airscrews would be embodied in the new aircraft." (Before you dismiss this as "propaganda" this information is reproduced, almost word for word, in Morgan and Shacklady) Wartime emergency: de Havilland worked overtime to manufacture, distribute and fit the CS conversion without a formal contract. In 44 days more than 800 propellers had been modified. Nothing like a wartime emergency to spur things along. And just to be clear, the same can apply to Merlins. Last edited by NZtyphoon; 04-17-2012 at 09:30 AM. |

|

#985

|

||||

|

||||

|

Quote:

The June 1940 Operating Instructions make no mention whatsoever for a higher boost at take off. Quote:

Notice the engine is modified during Service Inspection:  Quote:

Last edited by Crumpp; 04-17-2012 at 11:59 AM. |

|

#986

|

||||

|

||||

|

Quote:

I am sure you would love to think this was normal. Quote:

|

|

#987

|

|||

|

|||

|

Quote:

245 Squadron, May 1940, Hurricane 264 Squadron, May 1940, Defiant |

|

#988

|

|||

|

|||

|

Quote:

|

|

#989

|

|||

|

|||

|

Quote:

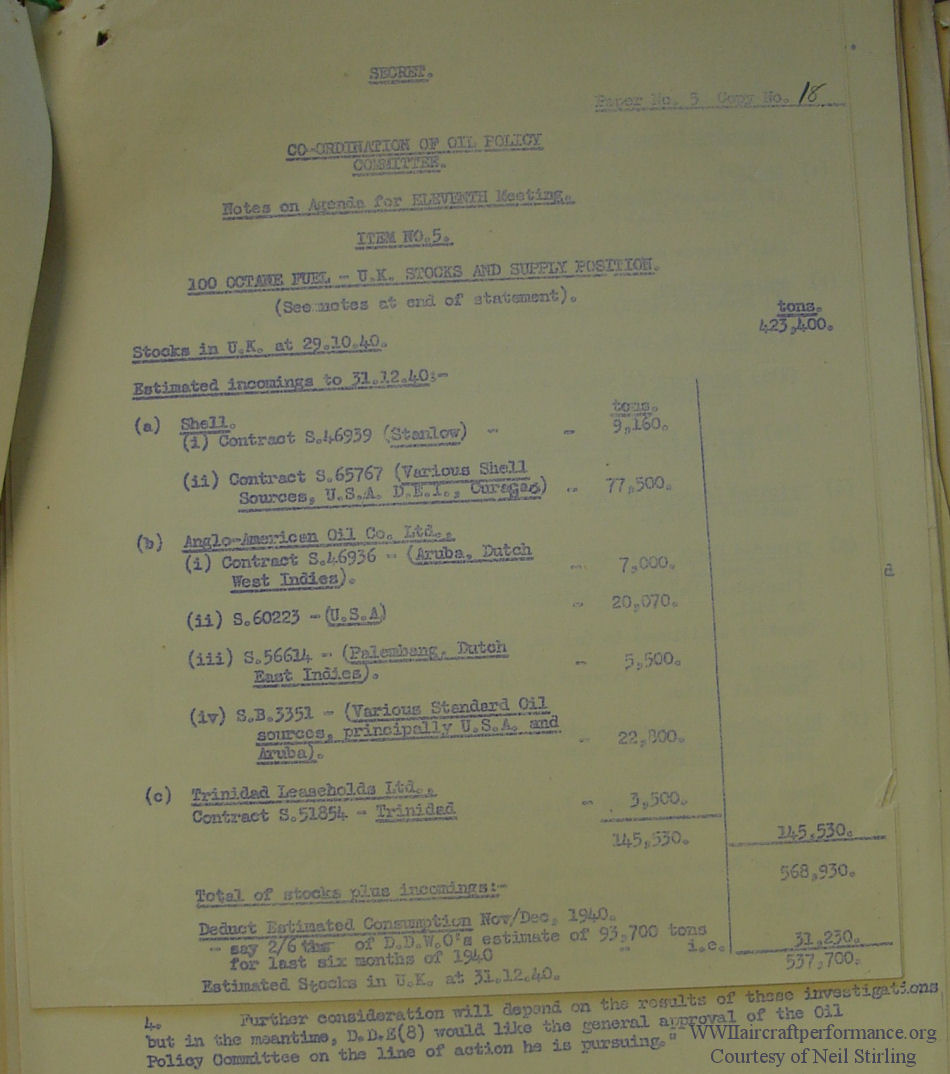

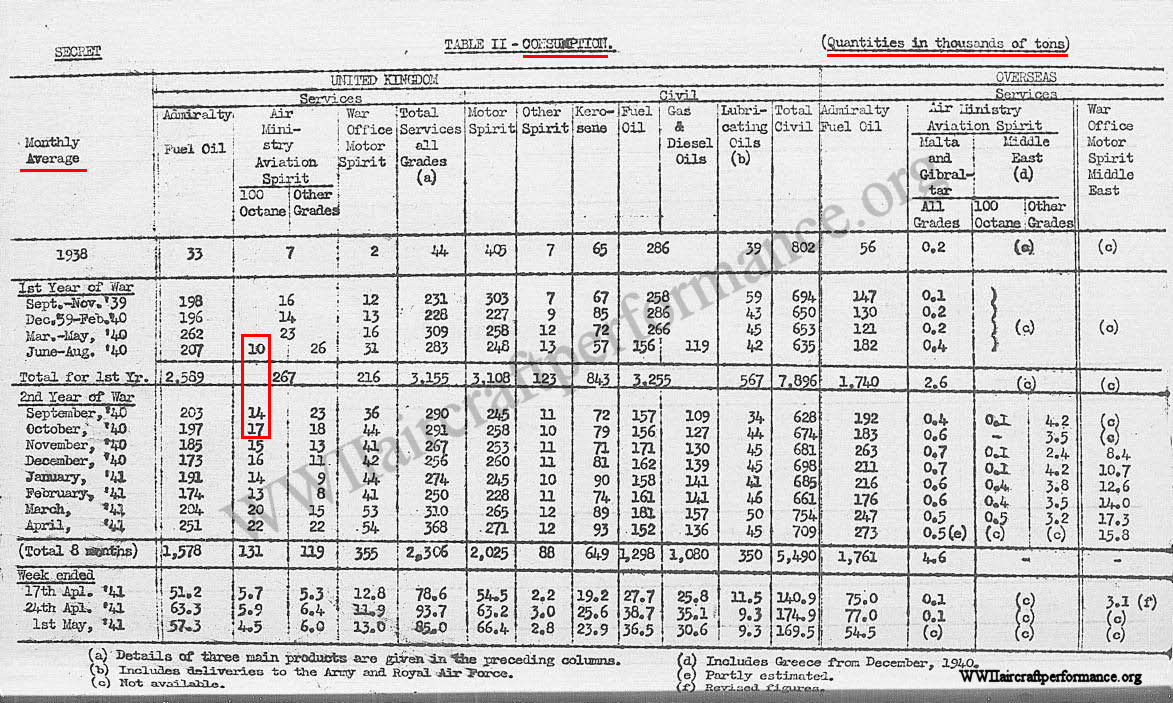

The important figure to my mind on that document is simply 100 Octane Fuel Stocks in U.K. 29.10.40 = 423,400 tons. Stocks of 100 octane at the end of December 1940 was 499,000 tons:

|

|

#990

|

|||

|

|||

|

Quote:

|

|

|

|